![]()

PORTABLE MODULAR CONVEYOR

By E2 Systems, LLC

Operator Control

• Conveniently controlled from operator’s position in loader cab

• Belt speed is controlled by the RPM of the loader engine

• Flow control valve will limit flow and speed if required

• Folding and Travel features controlled from controls on the conveyor base

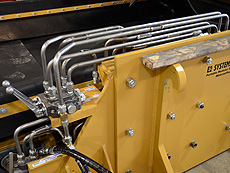

Hydraulic System

• Low torque, high speed hydraulic motor

• Loader pump capacity must match conveyor motor

• Minimum requirements, 40 g/m @ 3000 psi

• Oil supply to the conveyor motor is from loader

• A third valve function control is required

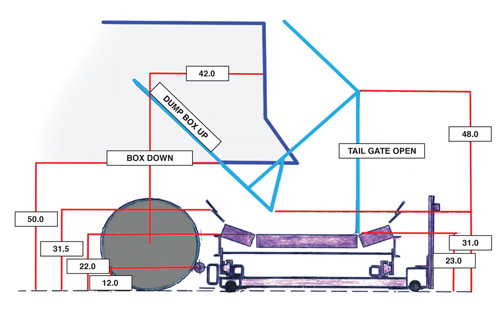

Receiving Hopper

• Receiving hopper will hold up to 2 cubic yards of material, but the placer is designed to move the material as it is loaded

• Hopper and conveyor can be hydraulically shifted to the left or right 2 feet of center to adjust dumping position

Conveyor Details

• Conveyor folds at midpoint to travel in a 10′ path while attached to loader

• Belt speed is approximately 550 f/m

• Belt width is 60″

• 3 ply belting

• Conveyor length is 21′ head pulley to tail pulley

• Top edge of hopper at rubber bumper is 30″

• Height clearance at center of belt in hopper 23″

Adaptability

• Conveyor may be rotated 180 degrees to accommodate desired travel direction

• Compatible with most manufactures wheel loaders and other modular equipment

• Can handle any flowable materials

Dimensions

• Working length attached to loader is 21’6″

• Traveling length attached to loader is 10′

• Unit width is 8’6′

• Unit is a legal load for transportation on flatbed trailer at 8’6″ x 21’6″

• Approximate weight is 9,800 pounds.